- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Application and Characteristics of Modified Plastic Granules (1)

2025-06-19

Automotive modified plastics refers to the original plastic basis, through the addition of additives, blending, filling and other methods to improve its physical, chemical or mechanical properties, in order to meet the automotive manufacturing industry on the special requirements of material performance. With the rise of car ownership in various countries, and driven by automobile lightweighting, the automotive industry has become the fastest growing field of modified plastics demand.

We provide modified plastic materials can solve the overall demand for automotive exterior parts, interior parts, structural parts material solutions to promote the development of automotive lightweight.

I. Modified PA

Characteristics: Modified PA has excellent mechanical properties, rigidity, toughness, abrasion resistance and mechanical vibration damping, good insulation and chemical reagent resistance.

Applications: intake manifolds, engine covers, radiator boxes, front-end components, automotive rocker covers, fan guards, and other parts in the hood.

II. Modified PET

Characteristics: Modified PET has excellent electrical properties, chemical reagent resistance, fatigue resistance, low water absorption, etc., and can still maintain its properties in a humid environment.

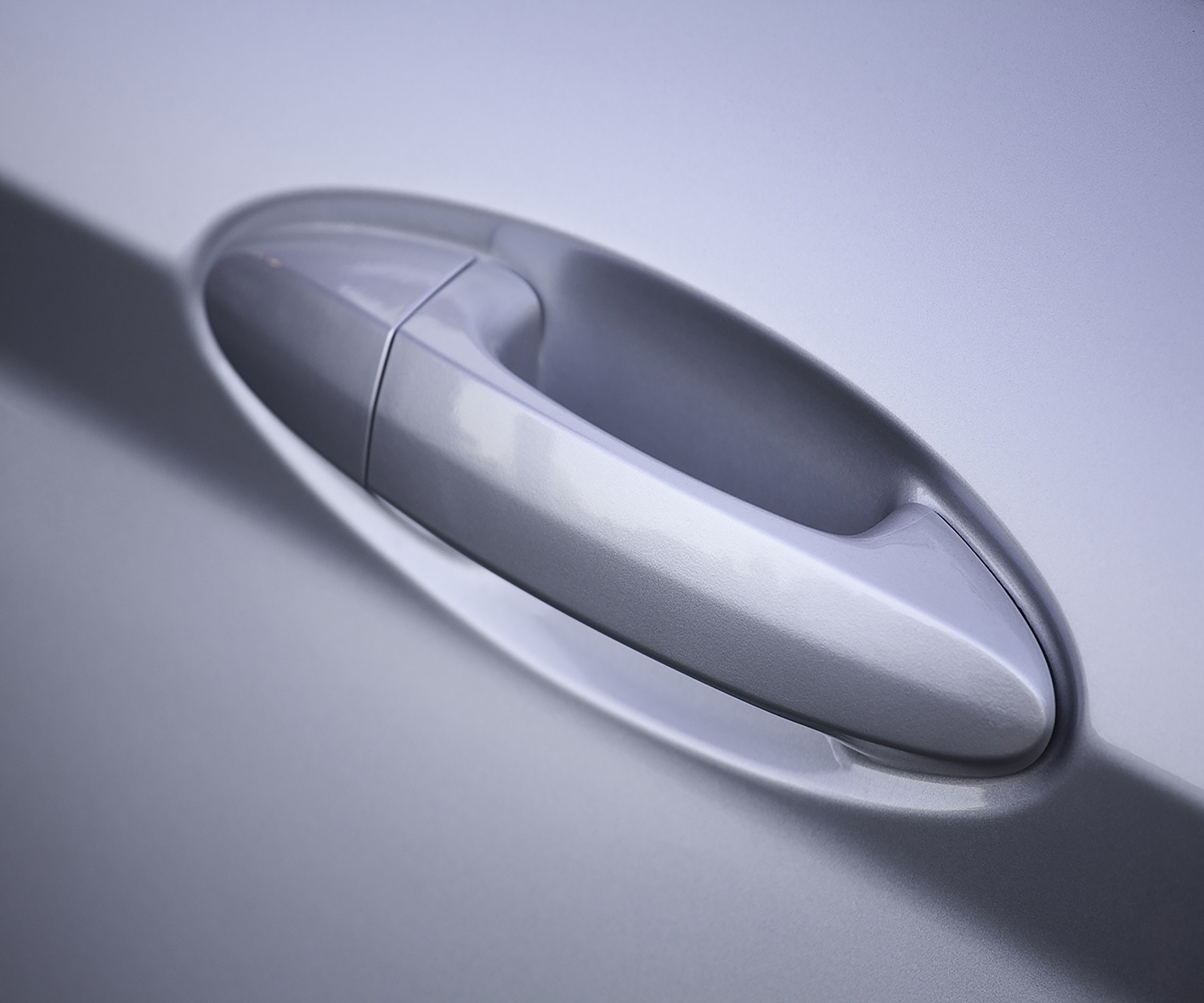

Applications: door locking systems, door handles, mirrors, bumpers, wiper handles, connectors, fuse covers, headlight frames, headlight bezels, car sockets and so on.

III. Modified PP

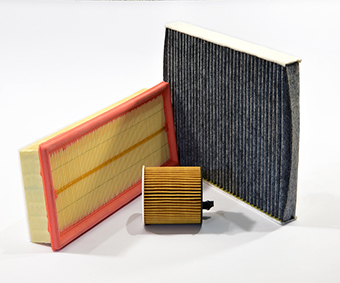

Characteristics: Modified PP has good chemical stability and heat resistance, low density, excellent weather resistance, corrosion resistance, impact resistance, scratch resistance, dimensional stability, easy to process molding, environmental protection.

Applications: instrument panels, bumpers, door panels, interior guards, front windshield, air intake filters, mudguards, radiator grills, pillars and so on.

IV. Modified PC

Characteristics: Modified PC has high impact strength and good transparency, can still maintain high mechanical strength in a wide temperature range, good electrical properties, high dimensional stability.

Applications: light guide pillar, automobile lamps, pillar decorative plate, air intake grille, new energy vehicle charging pile, automobile windows and so on.

V. Dyeing PMMA

Features: Modified PMMA (acrylic) is a material with excellent optical properties, second only to glass with high transparency, high weather resistance, high hardness, easy to process and molding characteristics.

Applications: automotive taillights, dashboard masks, interior lights, mirror shells, etc.

If you are interested in the above modified plastics, please feel free to contact us to obtain relevant materials and request samples.