- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

The Physical and Chemical Property Differences Between Erucamide and Oleamide

2025-02-17

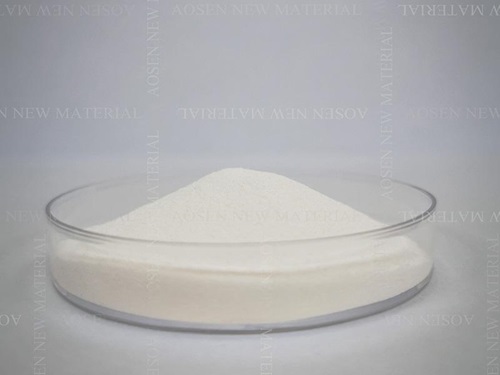

In the field of chemical engineering, both erucamide and oleamide are important additives, possessing physical and chemical characteristics such as lubricity and anti-stickiness. However, due to differences in their chemical structures, erucamide and oleamide exhibit significant variations in their physical properties.

1. Chemical Structure

Erucamide is derived from erucic acid and has 22 carbon atoms with a long carbon chain, with the double bond located at the 13th position. Oleamide, on the other hand, is derived from oleic acid, has a shorter carbon chain with only 18 carbon atoms, and the double bond is at the 9th position. The difference in carbon chain length and the position of the double bond is the root cause of the differences between erucamide and oleamide.

2. Melting Point

The melting point of erucamide is approximately 75-85°C, with the long carbon chain causing stronger intermolecular forces that require a higher temperature to break. In contrast, the melting point of oleamide is 68-76°C, with its shorter carbon chain resulting in weaker intermolecular forces and a lower melting point.

3. Mobility

During material processing and use, erucamide has a slower migration speed, thus providing a more durable lubricating effect for the material. Oleamide has a faster migration speed, quickly migrating to the surface of the material at the beginning of use, providing immediate lubrication.

4. Thermal Stability

Due to erucamide’s long-chain structure, erucamide exhibits better stability at high temperatures, making erucamide more suitable for high-temperature processing scenarios. Under high-temperature conditions, erucamide does not easily decompose or deteriorate. Oleamide's resistance to high temperatures is somewhat less.

5. Solubility and Compatibility

Erucamide has better solubility in non-polar solvents and better compatibility with high-density polymers. When combined with high-density materials, erucamide can disperse evenly, fully utilizing its performance advantages. Due to oleamide’s shorter carbon chain, oleamide may be more compatible with some low-density materials in certain situations, better integrating into low-density material systems.

In summary, in practical applications, if high-temperature processing is required or long-lasting lubrication effects are sought, erucamide should be given priority. If rapid demolding or application in low-temperature environments is needed, oleamide is the better choice. Aosen New Material is a professional and reliable supplier of Erucamide and Oleamide. Aosen provides customers with high-quality Erucamide and Oleamide at reasonable prices, feel free to contact us for samples!