- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

The Differences in Application Between Erucamide and Oleamide

2025-02-18

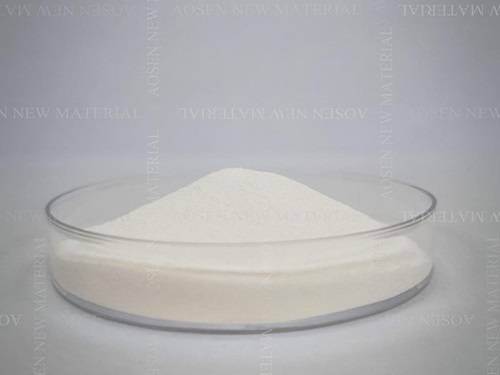

Erucamide and oleamide, though similar in name and use, are significantly different in practical application as important lubricants. Understanding the differences between erucamide and oleamide can help us accurately choose the appropriate materials for various industrial scenarios, enhancing production efficiency. Below, I will detail the application differences between erucamide and oleamide.

1. Plastics and Rubber Industry

(1) Erucamide is commonly used in the processing of plastics and rubber products at high temperatures. During high-temperature processing, the high melting point and good thermal stability of erucamide provide long-lasting lubrication and anti-sticking effects. For thick-walled products that require slow migration, erucamide is also an ideal choice.

(2) Oleamide is mainly applied in the processing of plastics at low temperatures, such as PE and PP films. Oleamide can quickly migrate to the surface of the film, effectively reducing friction, improving the processing performance and quality of the film. Especially in the production of transparent films, oleamide is widely used due to its minimal impact on transparency.

2. Coatings and Inks

(1) Erucamide is often used in the coating industry, where erucamide serves as a wear-resistant agent in coatings, enhancing the surface smoothness of the coating, increasing the wear resistance of the coating, and extending the service life of the coating.

(2) Oleamide is commonly used in the ink industry, mainly to improve printability, reduce ink caking, and allow for more uniform ink transfer during printing, thereby improving print quality.

3. Other Fields

(1) Food Contact Materials: Oleamide is more commonly used in the field of food packaging, while the application of erucamide in food contact materials is relatively less frequent.

(2) Antistatic Materials: Due to oleamide's fast migration speed, oleamide is more significant in antistatic applications, able to quickly disperse the charge on the surface of materials and reduce static accumulation.

In summary, erucamide is suitable for high-temperature environments, providing long-lasting lubrication, and is mainly used in engineering plastics, high-temperature films, etc.; oleamide is suitable for medium and low-temperature environments, with characteristics of rapid lubrication, and is commonly used in food packaging, transparent films, etc. Aosen New Material is a professional and reliable supplier of Erucamide and Oleamide. Aosen provides customers with high-quality Erucamide and Oleamide at reasonable prices, feel free to contact us for samples!