- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Glass Fiber Reinforced Polypropylene

Aosen New Material is a professional and reliable supplier of Glass Fiber Reinforced Polypropylene. Glass Fiber Reinforced Polypropylene, also known as PP+GF. Glass Fiber Reinforced Polypropylene is an advanced composite material made by integrating high-strength glass fibers into the polypropylene matrix. The Glass Fiber Reinforced Polypropylene provided by our company has passed the ROHS substance test of the European Union. with the reference to EU RoHS Directive 2011/65/EU and its amendment Directive EU 2015/863,to determine the Pb,Cd,Hg,Cr6+,PBBs,PBDEs,DBP,BBP,DEHP,DIBP content in the submitted sample , the result were complied. Aosen provide customers with various grades Glass Fiber Reinforced Polypropylene, if you’re looking for Glass Fiber Reinforced Polypropylene, feel free to contact us for sample!

Send Inquiry

Aosen Glass Fiber Reinforced Polypropylene

Chemical name: Glass Fiber Reinforced Polypropylene

Color: Black or other color according the requirement

Form: Granule

Smell: no special odor

Glass fiber reinforced PP is based on the original pure PP, adding glass fiber and other additives to improve the material's resistance, strength, and range of use.

Fiberglass reinforced polypropylene has significant effects on the performance of plastic products, improving the formability of plastics, and reducing costs.

① Glass fiber is a high-temperature resistant material, and modified polypropylene plastic has significantly increased its heat resistance;

② Due to the addition of fiberglass, the mutual movement between polymer chains in plastics is restricted, resulting in a significant decrease in the shrinkage rate of

reinforced plastics and a significant increase in rigidity;

③ Polypropylene plastic does not experience stress cracking, and its impact resistance is greatly improved;

④ Glass fiber is a high-strength material, which greatly enhances the strength of polypropylene, such as tensile strength, compressive strength, bending strength, and greatly improves it;

⑤ Due to the addition of glass fiber and other additives, the combustion performance of polypropylene plastic decreases significantly, making flame retardancy easier.

Properities of Glass Fiber Reinforced Polypropylene

|

Item |

Unit |

Result |

Standard |

|

Density |

g/cm3 |

1.146 |

ISO 1183 |

|

Shrinkage |

% |

0.3-0.4 |

Flow |

|

Tensile Strength |

MPa |

92 |

ISO 527 |

|

Elongation at break |

% |

3 |

ISO 527 |

|

Flexural Strength |

MPa |

127 |

ISO 178 |

|

Flexural Module |

MPa |

5600 |

ISO 178 |

|

Charpy Impact Strength,Unnotched |

KJ/㎡ |

48 |

ISO 179/1eU |

|

Charpy Impact Strength,Notched |

KJ/㎡ |

9 |

ISO 179/1eA |

|

Rockwell Hardness |

- |

110 |

ISO 2039-2 |

|

Flame retardancy |

Class |

HB |

UL-94 |

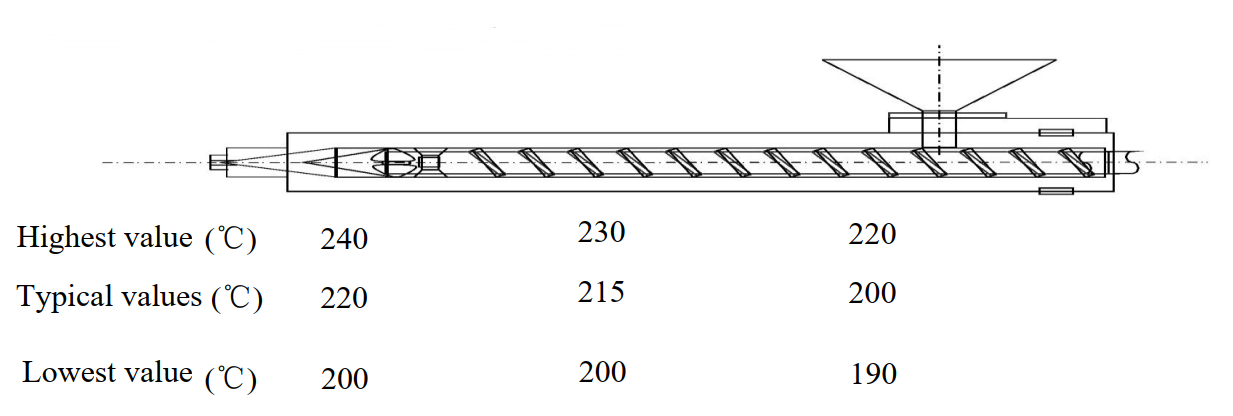

Glass Fiber Reinforced Polypropylene Recommended processing conditions

A. Dry: 80℃, 2~4h。

Depending on the following variables

a) humidity

b) Proportion of recycled materials

c) Storage conditions

B. Set temperature of ejector sleeve

C. Mold temperature

Range 20~60℃

D. Precautions for storage (use):

The product should be stored in a dry environment below 50 ℃ and avoid ultraviolet radiation. Improper storage will cause degradation, resulting in peculiar smell and have a negative impact on the physical properties of the product

Packaging And Transportation of Glass Fiber Reinforced Polypropylene

Considering the characteristics of the product, it should be loaded and discharge lightly during transportation to prevent collision, rain, sun exposure, and pollution. Products should be stored in a ventilated, dry, and clean warehouse, and stacking is strictly prohibited.

The Packaging is 25kg/ Bag